TUBULAR INSPECTION SERVICES (IRIS, RFET, ECT, NFL)

Tube Inspections have been carried out by ADVANCED NDT SERVICES LLP personnel for the, Petrochemical and Power Generation. We specialize in Eddy Current and Ultrasonic techniques for both ferrous and non-ferrous tubing. Our line of techniques includes:

- Remote Field Technology (RFT- Ferrous Tubing)

- Near Field Testing (NFT – Fin Fans)

- Eddy Current Testing (ECT- Non-ferrous Tubing)

- Internal Rotary Inspection System (IRIS-Ultrasonic Testing all materials).

- Surface Eddy Current

HEAT EXCHANGER INSPECTION

Scheduled shutdowns present an opportunity for planned inspection programs which enable continued operation of critical plant equipment by minimizing unexpected failures. Prior to deciding which techniques are most suitable for your needs the following items should be considered: number of tubes to be inspected; cleanliness of tubes and time available for inspection.

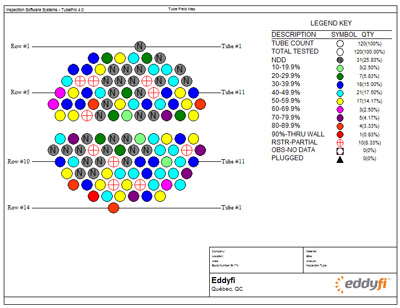

Eddy Current Testing (ECT): This is the most common technique utilized for the inspection of non-ferrous tubing, the technology is very reliable and can determine tube condition in relation to general wall reduction and the presence of local defects such as pitting and cracking with a high probability of detection when using the correct probes. Standard inspection technique for smooth tubing utilizes two separate channels for data acquisition; Absolute (wall reduction) and Differential (local defects). When inspecting finned tubing (chillers) an A/C probe is used to reduce noise associated with fins. Detailed analysis can be performed using software tools which can determine location of defects in relation to ID/OD of tube wall by Phase Analysis from depth curves which are generated from calibration standard. Software tools also allowing for mixing of baffle signature to evaluate flaws hidden behind baffle supports

Remote Field Testing (RFT): This is a fast-reliable screening tool for the condition assessment of ferrous tubing (carbon steel, ferritic stainless steel and Duplex). Works typically at very low frequencies (100 Hz to 1 kHz) and very high signal gains (> 80 dB) can inspect up to 12 mm (1/2 in.) of carbon steel pipe. Typically, two channels are used for examination, Absolute for wall thinning and Differential for localized defects RFT is very good at wall thinning measurement but less performing to pitting (as compared to ECT). To improve inspection results it is always advised to perform cleaning of the internal bore of tubes with some form of water jet lancing tool.

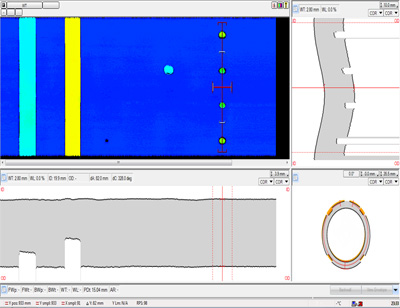

IRIS – Internal Rotary Inspection System: This is an ultrasonic technique for condition assessment of tubing of all materials with a tube wall thickness greater than 1mm. The technology can precisely measure remaining wall thickness from corrosion, erosion, pitting and wear associated with baffle supports. However, it requires a very high standard of cleaning and is a much slower technique than the ECT or RFT test methods. It is not possible to detect cracking with IRIS. The system uses a rotating turbine head with a transducer sending a single into tube wall via an angular mirror. The image displayed can be seen as a B-Scan (Cross-sectional view) and also in a C-Scan (Development of Longitudinal axis of tube).

Allow the experts at ADVANCED NDT SERVICES LLP (ANS) develop an inspection solution for your company, we can provide the Answer to obtaining the information you require to continue the safe operation of your plant equipment. Our team has over 15 years’ experience in delivering advanced ultrasonic technology in the field, prior to their acceptance into construction codes as standard practices. We aim for quality and integrity every day.

Detailed Reports

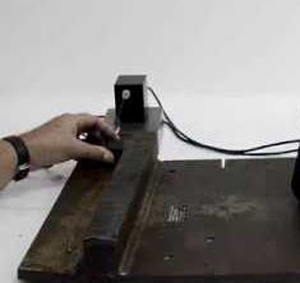

IRIS Technique

Our Team During Inspection

PHASED ARRAY ULTRASONIC TESTING (PAUT)

Phased Array Ultrasonic Testing (PAUT) used for flaw detection, sizing, and imaging. PAUT technology is the ability to modify electronically the acoustic probe characteristics.

The Phased Array Ultrasonic Testing (PAUT) and Time of Flight Diffraction

(TOFD) technologies have made rapid changes in inspection and reliability in various industries.

These ultrasonic testing techniques are rapidly replacing conventional radiography. A major advantage in replacing RT with PAUT & TOFD is reducing the radiation risks apart from increased probability of detection (POD), production rate and better sizing of the discontinuities.) Advanced NDT Phased Array Ultrasonic Boiler Tube Inspection applications have become almost the norm in many areas of industry today. The benefits of this non-destructive testing technology being the ability to store a full inspection record. The visual display of combined A-Scan, B-Scan, C-Scan and S-Scan gives a simplified understanding of flaw type and associated dimensions.Phased Array advanced ultrasonic’ s has the advantage over conventional manual ultrasonic NDT techniques because it is possible to inspect large volumes of welds and material from a fixed location. This allows otherwise difficult geometries to be inspected. Thus, the technique can be utilized for a very large variation of applications from standard butt welds in vessels and piping to more complex sweep lets, flanges, railway tracks, nozzles, turbine blades and many more.

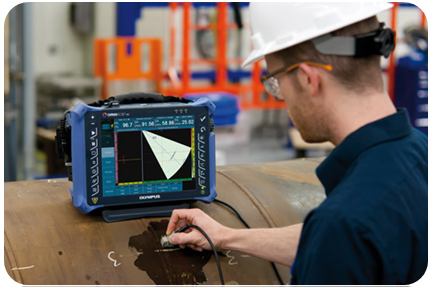

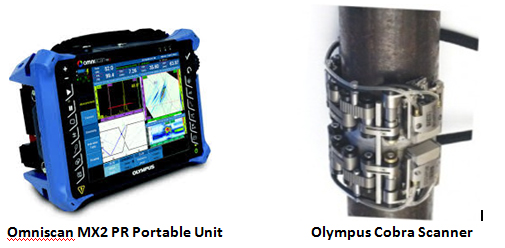

The majority of Phased Array equipment used on site is very portable and generally used in conjunction with manually driven encoded scanning devices, although much more elaborate robotic designs are available. The units vary in hardware from 16 to 64 element pulser configurations that determine the thickness of materials that can be covered within a single scan.

It is important that the individuals performing these examinations are trained, certified correctly in both the technology and actual equipment being operated. Detailed scan plans are required prior to examinations being performed and correct calibration/reference blocks and performance demonstration welds to correctly validate inspection technique.

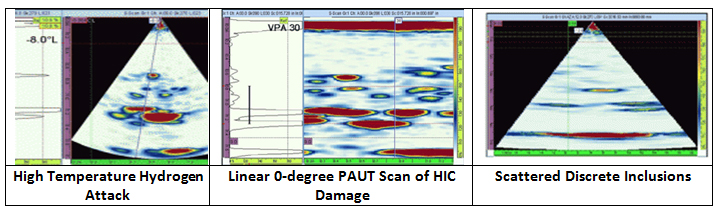

Phased Array Technology has also been utilized to perform Ultrasonic examinations for the evaluation of environmental damage mechanisms such as HIC, SOHIC, SCC and HTHA. The sectorial image produced from a phased array scan can often reveal whether stepwise cracking is present between hydrogen blisters that would not be noted from 0 longitudinal inspection. Field trials have determined Phased Array techniques to be the most successful in identifying and sizing Stress Corrosion Cracking (SCC) in stainless steel piping butt welds. The image below indicates typical SCC detected using Phased Array techniques.

Allow the experts at ADVANCED NDT SERVICES LLP (ANSLLP) develop an inspection solution for your company, we can provide the Answer to obtaining the information you require to continue the safe operation of your plant equipment. Our team of NDT technologists has over 15 years’ experience in delivering advanced ultrasonic technology in the field, prior to their acceptance into construction codes as standard practices. We aim for quality and integrity everyday

TIME-OF-FLIGHT-DIFFRACTION (TOFD)

Time-of-flight-diffraction (TOFD) is an accurate ultrasonic method for the detection and sizing of flaws in new construction and in-service welds and components, and is also used for defect monitoring on in-service welds and components.

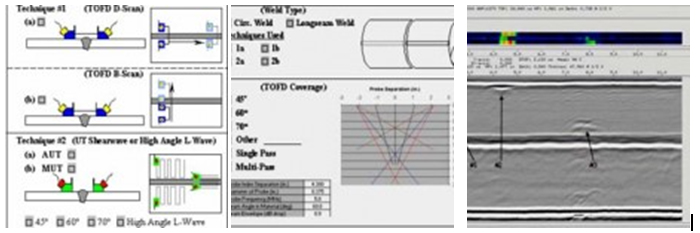

TOFD Technique

Schematic Drawing of TOFD Technique

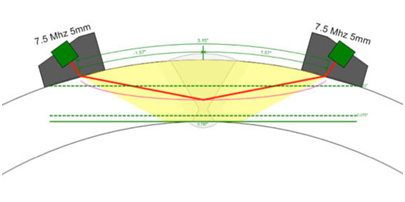

TOFD employs two longitudinal wave (L-wave) angle beam transducers arranged diametrically on opposite sides straddling the weld or base material under examination. One transducer acts as a transmitter of ultrasonic energy, while the other receives the returning signals. The transducer, pulser, and amplifier characteristics are selected to generate a broad distribution of energy allowing for full weld coverage with single scans. An electronic encoder records the probes position along the weld during the scan which enables a real time display and recording of the digital images.

Defect detection is identified when there is a diffraction of the ultrasonic wave from the tip(s) of the defect(s). Measurement of the time-of-flight of the pulse allows the depth of a defect tip to be calculated using the TOFD technique. This allows the NDT technician to size the indications to determine acceptance or rejection per the applicable code and/or client specification.

Benefits of TOFD include:

Can be applied to new construction welds, in lieu of radiography (ASME Code Case 2235), providing an excellent record of vessel or pipe condition at birth.

Can also be used for in-service defects, such as cracking, corrosion, erosion, etc. Has a very high temperature limitation (700 F), with slight loss in sensitivity.

Detects flaws regardless of their orientation within the weld.

Can be applied without the need to shut down other activities in the area (which RT demands).

Can be applied either during welding or immediately after completion of the weld, allowing instant determination of weld quality.

Allows flaw growth monitoring for run/repair decisions.

The TOFD Advanced NDT technique is faster, more reliable, accurate and comprehensive in terms of coverage, and more cost-effective in identifying those flaws affecting the reliability of plant assets:

It is faster and overall, less expensive than radiography

It is more flexible and has more applications than standard ultrasonic techniques.

Specific proposals and alternative applications are available upon request.

REMOTE VISUAL INSPECTION (Borescope/Videoscope)

Borescope are used for visual inspection work where the area to be inspected is inaccessible by other means. Similar devices for use inside the human body are referred to as endoscopes.

Borescope are mostly used in non-destructive testing techniques for recognizing defects or imperfections

MRUT (Medium Range UT)

MRUT (Medium Range UT) describes a suite of techniques that permit covering an area between approximately 25mm to 3000mm from the location where the inspection is performed. MRUT uses guided wave and/or bulk wave techniques and complements LRUT (Long Range UT) by covering the near field area where LRUT cannot be used. MRUT techniques are mainly designed for fast scanning and detection (qualitative assessment), although in some circumstances they can provide relatively accurate measurements (quantitative assessment).

SRUT – Short Range Ultrasonic Testing

SRUT – Short Range Ultrasonic: we provide Short Range Ultrasonic Testing (SRUT) which can be used for tank floor inspection vessel inspection for detection of corrosion CUI detection for piping or corrosion on under pipe support. Guided Wave is a technique which uses low frequency sound waves to flood thin wall material and then reflect back at interfaces such as cracking or corrosion/pitting. The guided wave technique is to be used as a screening tool only as remaining wall thickness measurements cannot be achieved. However, reflection distance can be measured with precise accuracy.

LRUT-Long-Range Ultrasonic Testing

LRUT – Long Range Ultrasonic Testing : we offer Long Range Ultrasonic Testing – LRUT has been employed for screening piping systems above ground as a result of the high production coverage rates as opposed to manual techniques, but it still remains the only reliable technique for screening pipe systems underground or underwater where access is often limited or very costly to gain access for manual contact techniques. The technology continues to be improved and the number of applications utilizing this system has greatly expanded.

LRUT – Long Range Ultrasonic Testing: the technology operates by placement of an array of probes placed in a belt, circumferentially wrapped around the pipe being inspected. The system then generates ultrasonic guided waves longitudinally down the length of pipe, distance covered by the ultrasonic waves is dependent on a number of factors related to pipe coating, branch connections, fittings and above ground or buried locations. The system can inspect both directions from each inspection location and therefore can maximise production.

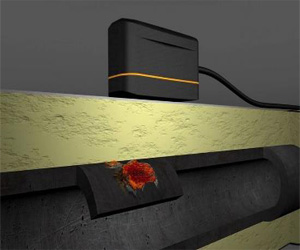

PULSED EDDY CURRENT TESTING (PECT)

Pulsed Eddy Current Testing (PECT) is an inspection technique used for corrosion under insulation (CUI) screening on carbon steel structures as pipes, vessels, tanks and spherical tank legs without the need of contact with the steel surface. PECT is a static technique able to measure spot percentage variations in steel thickness through any non-conductive and non-magnetic material between the sensor and steel surface such as air, insulation material, concrete, plastics, coatings, paint, sea water, marine growth, deposits, oil, etc. PECT is a comparative technique where the percentage variations measured on the specimen are compared with a calibration value which is always assumed to be the full wall thickness..